In today's fast-paced construction world, expanded polyolefin foam has gained significant attention. This versatile material offers various applications, making it an ideal choice for multiple projects. Its lightweight properties and excellent insulation capabilities are just a few reasons why builders and designers are drawn to it.

Utilizing expanded polyolefin foam can enhance product durability while reducing overall weight. Imagine creating energy-efficient structures with superior thermal performance. The material can be used for packaging, automotive components, and even protective barriers. Each project presents unique challenges, requiring careful consideration of foam's properties.

However, not all applications may benefit equally from expanded polyolefin foam. Integration often demands experimentation and adjustments. Reflecting on specific project needs is essential. Understanding the balance between cost and performance can shape the success of your endeavor. With its potential, you may find new ways to leverage expanded polyolefin foam effectively.

Expanded polyolefin foam, often referred to as EPO foam, is gaining popularity in various industries. This material is lightweight and versatile. It offers excellent cushioning and insulation properties. EPO foam is resistant to moisture, chemicals, and impact, making it ideal for protective packaging. It is commonly used in automotive applications, sports equipment, and construction.

In addition to its protective qualities, EPO foam is easy to work with. It can be cut, shaped, and molded without much effort. This adaptability allows it to fit into many different projects. However, one must consider its limitations. While it holds up well in many environments, extreme temperatures can affect its performance. It's essential to test samples in specific conditions before widespread use.

Many creative applications utilize EPO foam’s unique properties. From custom displays to soundproofing solutions, its potential is impressive. Yet, the journey of integrating this material might not always go smoothly. Some projects may reveal unforeseen challenges, requiring adjustments and critical thinking. Embracing these imperfections can lead to innovative outcomes and better results in future endeavors.

Expanded Polyolefin (EPO) foam has gained significant attention in various industries. Its lightweight and flexible nature makes it suitable for numerous applications. In packaging, EPO foam protects fragile items during transport. It absorbs shocks effectively, reducing the risk of damage. Lightweight packaging helps reduce shipping costs and improves sustainability.

In the automotive sector, EPO foam is utilized for noise reduction and thermal insulation. It reduces vibrations inside vehicles, creating a quieter ride. Additionally, its resistance to moisture makes it ideal in areas with high humidity. However, ensuring proper installation is crucial. Even small gaps can lead to inefficiencies.

The construction industry also benefits from EPO foam. It acts as an excellent insulation material, keeping energy costs down. Its ease of handling allows for faster installation. Yet, some builders may overlook the importance of choosing the right thickness. This can impact overall performance.

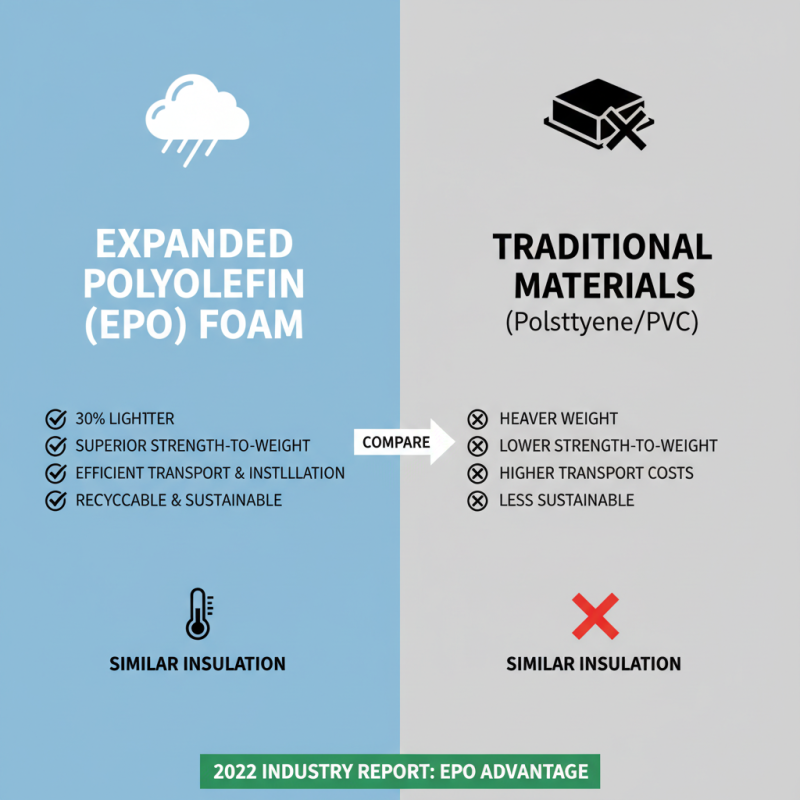

When comparing expanded polyolefin foam (EPO) to traditional materials like polystyrene or PVC, several key factors emerge. EPO boasts a remarkable density-to-weight ratio. According to a 2022 industry report, EPO can achieve similar insulation properties as these traditional materials while being 30% lighter. This weight advantage can enhance project efficiency, especially in transportation and installation phases.

However, there are considerations. EPO might not always have the same load-bearing capacities as more robust traditional materials. For instance, in structural applications, the compressive strength of EPO is lower than that of plywood. This can limit its use in certain scenarios where heavy loads are involved. Yet, its resistance to moisture and chemicals is significantly better than that of polystyrene, offering a longer lifespan in specific environments.

Another aspect to reflect on is cost. While EPO is gaining popularity, it often comes at a higher initial investment compared to PVC. A study published in the Journal of Materials Science projected that over time, reduced maintenance and better performance can offset this initial cost. Still, this is not universally applicable. Such reflections help determine the best material for specific project needs.

Expanded Polyolefin Foam (EPP) is a versatile material used in various projects. Its lightweight nature makes it ideal for packaging, insulation, and cushioning applications. When handling EPP, it’s crucial to maintain proper storage to avoid deformation. Keep the foam in a cool, dry place. This prevents any warping or damage to the material.

Cutting EPP requires specific tools to achieve clean edges. A hot wire cutter works well, but it’s vital to control the temperature. Too high a temperature can melt the foam, leading to messy cuts. After cutting, always check for sharp edges. Smooth them to ensure safe handling. Remember, some projects may require adhesive for assembly. It’s essential to test adhesives on scrap pieces first. Sometimes, the foam’s texture may not bond well with certain glues.

EPP can be painted or laminated for aesthetic purposes. However, not all paints are suitable. Some may not adhere properly or could damage the foam. Test small areas first to see if the paint reacts negatively. Also, consider the environment where the finished product will be used. Exposure to moisture or high heat may affect the foam's performance. Constantly review best practices to ensure that your projects meet both quality and safety standards.

The utilization of Expanded Polyolefin Foam (EPO) is evolving rapidly. Current reports indicate that the global market for EPO is projected to reach $2.5 billion by 2026, showing a significant growth trend. This growth is driven by its diverse applications, particularly in packaging and automotive industries. EPO's lightweight and excellent cushioning properties make it an ideal material for protective packaging.

Future trends suggest increased emphasis on sustainability. Many manufacturers are now focusing on recycling EPO materials. This could reduce waste and promote a circular economy. Recent studies show that companies adopting recycled EPO can reduce their carbon footprint by 30%. However, the challenge remains in developing efficient recycling technologies. This inconsistency may hinder widespread adoption.

In the automotive sector, EPO could play a crucial role in enhancing vehicle designs. The material offers energy absorption, which contributes to safety features. However, not all manufacturers are equipped to leverage EPO's full potential. Education and resources for designers are often inadequate. As the industry evolves, addressing these gaps will be key to maximizing EPO's capabilities in future projects.

| Application Area | Benefits | Future Trends | Sustainability Impact |

|---|---|---|---|

| Automotive | Lightweight, sound insulation | Increased use in electric vehicles | Recyclable materials |

| Packaging | Shock absorption, reduced weight | Biodegradable polyolefin options | Lower carbon footprint |

| Construction | Thermal insulation, moisture resistance | Smart building integrations | Energy-efficient solutions |

| Consumer Electronics | Protection, custom shapes | Increased customization options | Reduced electronic waste |

| Healthcare | Sanitary, cushioning for equipment | Advancement in hygienic packaging | Enhanced reusability |

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.