In today's world, energy efficiency has become a paramount consideration for homeowners seeking to reduce both their environmental impact and utility costs. Among the various insulation materials available on the market, **polyolefin foam insulation** stands out due to its remarkable thermal performance and versatility. This innovative insulation solution not only helps maintain comfortable indoor temperatures but also plays a significant role in optimizing energy consumption. With increasing awareness about climate change and rising energy prices, many individuals are searching for effective ways to enhance their homes’ energy efficiency.

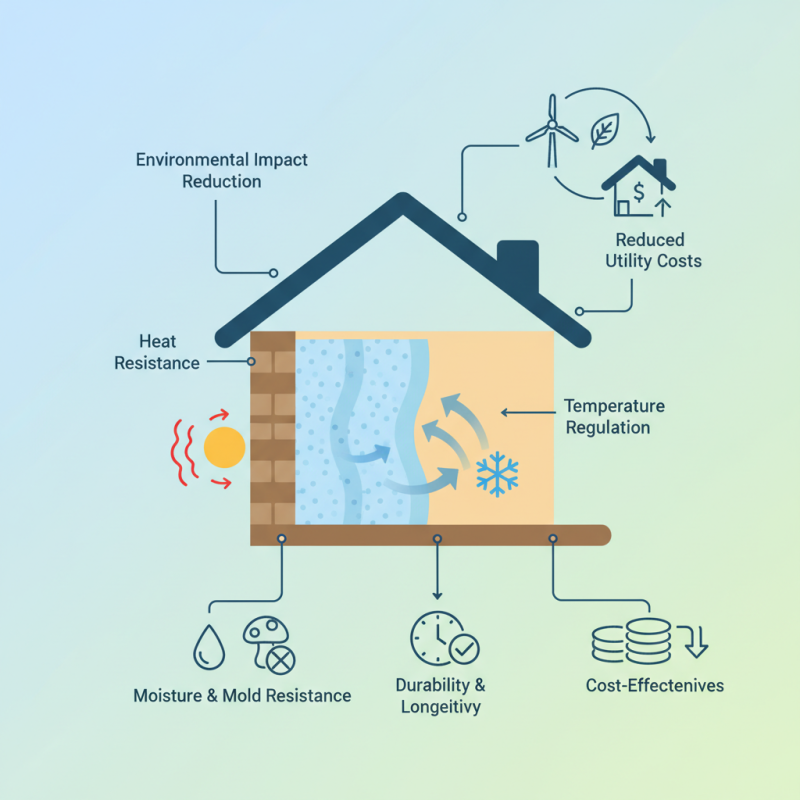

Polyolefin foam insulation is engineered to provide superior resistance to heat transfer, making it an ideal choice for various applications, from walls and roofs to floors and pipes. Its lightweight and flexible properties allow for easy installation, overcoming many challenges associated with traditional insulation methods. Furthermore, polyolefin foam is not only resistant to moisture and mold but is also durable and long-lasting, which adds an additional layer of cost-effectiveness over time. As households transition toward sustainable practices, selecting polyolefin foam insulation emerges as a practical solution that aligns with both environmental goals and budgetary considerations.

In conclusion, the choice of polyolefin foam insulation embodies a commitment to energy efficiency, sustainability, and overall comfort in the home. As homeowners strive to make informed decisions about their living environments, understanding the benefits of this insulation type can lead to significant long-term advantages.

Polyolefin foam insulation is emerging as a popular choice in residential energy efficiency, characterized by its unique composition and performance benefits. Comprised primarily of polyethylene and polypropylene, polyolefin foam is known for its closed-cell structure, which provides excellent thermal resistance and moisture barrier properties. According to the U.S. Department of Energy, the effectiveness of insulation can significantly affect energy consumption for heating and cooling, with a properly insulated home saving homeowners up to 20% on their energy bills.

Moreover, polyolefin foam insulation boasts a high R-value per inch, often ranging between R-3.6 and R-4.2, making it one of the more efficient insulating materials available. This high thermal resistance minimizes heat transfer, essential for maintaining consistent indoor temperatures regardless of external conditions. Additionally, studies from the North American Insulation Manufacturers Association indicate that by using high-performance insulation materials like polyolefin foam:

Providing lasting benefits that align with sustainable building practices.

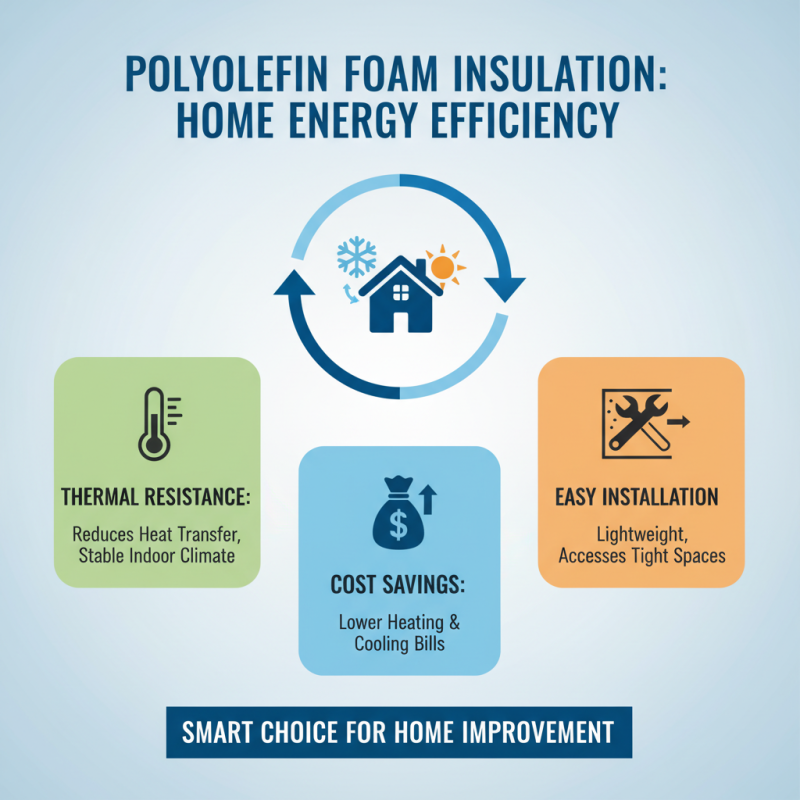

When it comes to enhancing energy efficiency in homes, polyolefin foam insulation stands out due to its exceptional performance characteristics. One of the primary benefits is its excellent thermal resistance, which significantly reduces heat transfer. This helps maintain a more comfortable indoor climate, potentially lowering heating and cooling costs. With its lightweight nature, polyolefin foam can be easily installed in various applications, ensuring that even hard-to-reach areas are effectively insulated. This ease of installation contributes to a more streamlined building process, making it an attractive choice for home improvements.

In addition to thermal resistance, polyolefin foam offers remarkable moisture resistance, preventing mold and mildew growth. This feature is particularly important in areas prone to humidity, as it helps maintain indoor air quality and protects structural integrity. Furthermore, polyolefin foam is environmentally friendly, being fully recyclable and produced with less energy compared to traditional insulation materials. Its durability adds to its longevity, requiring less frequent replacements, which not only conserves resources but also contributes to a sustainable home design. Overall, polyolefin foam insulation presents a compelling option for homeowners seeking to increase energy efficiency while promoting a healthier living environment.

When considering insulation materials for energy efficiency, polyolefin foam stands out against traditional options like fiberglass, cellulose, and foam board. One of its primary advantages is its excellent thermal resistance, which contributes to a reduced need for heating and cooling, ultimately lowering energy costs. Compared to fiberglass, polyolefin foam has a higher R-value per inch, allowing for thinner applications without sacrificing performance. Its closed-cell structure also provides superior moisture resistance, making it less susceptible to mold and degradation over time, which can be significant drawbacks of other insulation materials.

Furthermore, polyolefin foam is lightweight and easy to handle, making it an attractive option for homeowners and contractors alike. In contrast to cellulose insulation, which can settle and lose effectiveness over time, polyolefin foam maintains its insulating properties without the concern of settling or air infiltration. Additionally, it is less irritating to work with than fiberglass, reducing health risks during installation. This comparative analysis highlights how polyolefin foam insulation not only meets energy efficiency standards but also provides durability and ease of installation, establishing it as a preferred choice for many residential applications.

This bar chart compares the average R-Value per inch of different insulation materials commonly used in homes. Polyolefin foam offers a competitive R-Value, making it a suitable choice for energy efficiency.

When considering the installation of polyolefin foam insulation, it is essential to understand the process and key considerations involved. The installation typically begins with assessing the area to be insulated. Homeowners should determine the necessary thickness of the insulation based on local climate and energy efficiency goals. Once the area is prepared by ensuring it is clean and free of debris, polyolefin foam panels can be cut to the appropriate size and easily adhered to walls, floors, or ceilings using compatible adhesives.

Attention must also be given to sealing gaps and joints during installation to maximize energy efficiency. This can be achieved by using high-quality tape or sealants designed for foam insulation. Proper ventilation is another crucial consideration; while polyolefin foam provides excellent insulation properties, adequate airflow must be maintained to prevent potential moisture buildup and ensure indoor air quality. By following these guidelines, homeowners can effectively enhance their energy efficiency through polyolefin foam insulation while ensuring a smooth installation process.

Polyolefin foam insulation is rapidly gaining recognition for its long-term performance and minimal environmental impact, making it a valuable choice for enhancing energy efficiency in homes. According to the Energy Information Administration, effective insulation can reduce energy loss by up to 35%. Polyolefin foam boasts excellent thermal resistance, which is essential for maintaining a comfortable indoor climate while reducing heating and cooling costs. This insulation material is durable, resistant to moisture, and does not deteriorate over time, ensuring that its insulating properties remain effective for decades.

From an environmental perspective, polyolefin foam is produced using processes that minimize waste and energy consumption. Recent studies indicate that the production of polyolefin foam can result in a carbon footprint that is significantly lower than traditional insulation materials. Additionally, its recyclability contributes to a circular economy, promoting sustainability within the building industry. The closed-cell structure of polyolefin foam further enhances its capabilities by providing superior resistance to air and moisture infiltration, which can help reduce the overall energy consumption of a home.

**Tips:** When considering insulation options, look for materials with a high R-value to ensure optimal energy efficiency. Additionally, evaluate the recyclability of insulation products to support sustainable building practices. Always consult with a qualified insulation contractor to determine the best solutions tailored to your home’s specific needs.

| Dimension | Value | Remarks |

|---|---|---|

| Thermal Resistance (R-value) | 3.0 - 6.0 per inch | Effective thermal insulation for energy savings |

| Service Life | Over 50 years | Long-term durability compared to alternatives |

| Recyclability | Highly recyclable | Environmentally friendly end-of-life options |

| Water Absorption | < 0.5% by volume | Excellent moisture resistance |

| Sound Absorption | NRC up to 0.75 | Good for acoustic insulation |

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.