In today's fast-paced world, the quest for tranquility within our living and working spaces has never been more crucial. According to a report by the World Health Organization, noise pollution is responsible for various health issues, including stress and sleep disturbances, affecting millions globally. As urban environments become increasingly chaotic, soundproofing solutions have become a necessity rather than a luxury. One of the most effective methods to combat unwanted noise is through the use of noise insulation foam, which serves to minimize sound transmission and create a serene atmosphere.

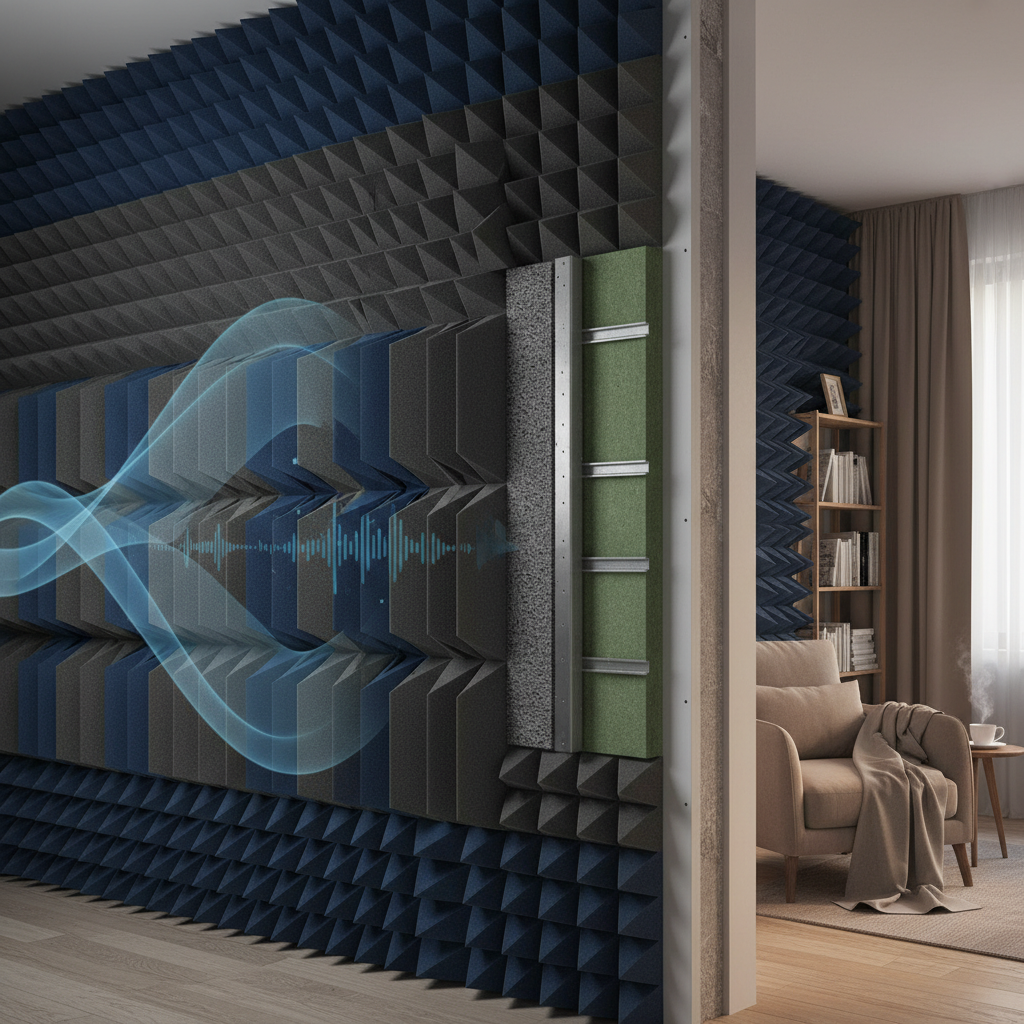

Noise insulation foam works by absorbing sound waves, significantly reducing their strength before they can travel throughout a space. A study published in the Journal of Acoustical Society of America indicates that the right type of soundproofing materials can reduce noise levels by up to 50%. This makes noise insulation foam an essential component for homes, offices, and other venues where acoustic clarity is desired. Whether you’re looking to create a quiet home theater, a peaceful office environment, or a sound-controlled studio, the strategic application of noise insulation foam can provide unparalleled benefits in soundproofing your space.

Noise insulation foam is a crucial element for achieving optimal soundproofing in both residential and commercial spaces. One of the primary benefits of using this foam is its ability to significantly reduce sound transmission. Whether it's the annoying chatter from neighbors, the hum of traffic, or the buzz of an office environment, noise insulation foam acts as a barrier that absorbs sound waves, leading to a quieter and more peaceful atmosphere.

Additionally, noise insulation foam contributes to improved acoustic quality in a room. By minimizing echoes and reverberations, it enhances the clarity of sound, making it a popular choice for music studios and home theaters. The versatile applications of this foam also include usage in recording studios and conference rooms, where clear communication and audio fidelity are paramount. With its ease of installation and effectiveness, noise insulation foam not only creates a more serene environment but also adds value to your space by promoting a better quality of life and enhanced productivity.

When it comes to soundproofing a space, selecting the right type of foam materials is crucial. Two popular options are acoustic foam and mass-loaded vinyl (MLV). Acoustic foam, characterized by its unique wedge or pyramid shapes, absorbs sound waves and minimizes echo. This type of foam is particularly effective for environments like recording studios or home theaters, where clear audio quality is paramount. Its lightweight and easy installation make it a favorite among DIY enthusiasts and professionals alike.

On the other hand, mass-loaded vinyl offers a different approach to soundproofing. This dense, flexible material effectively blocks sound transmission due to its heavy mass. It works exceptionally well in applications such as walls, ceilings, and floors, reducing noise from both adjacent rooms and outside sources. While it may not absorb sound like acoustic foam, MLV is ideal for anyone seeking to create a quiet, serene environment in their homes or workplaces. By comparing these foam materials, individuals can determine the best solution to meet their specific noise insulation needs.

When selecting the right noise insulation foam for your needs, it's essential to consider several factors to ensure maximum soundproofing efficiency. First, assess the specific type of noise you wish to block—whether it's airborne noise from conversations or footsteps, or impact noise from vibrations. This will help determine the density and thickness of the foam required. High-density foam is generally more effective in absorbing sound waves, while thicker panels can provide better insulation for lower frequencies.

Additionally, consider the room's dimensions and its purpose. For smaller spaces, opting for lightweight foam that can be easily installed on walls and ceilings may be preferable, while larger areas may benefit from more robust options, such as acoustic panels and bass traps.

Don’t overlook the aesthetic aspect; choosing foam with a color or design that complements your space can enhance your environment while serving a crucial functional role. By carefully analyzing these elements, you can make an informed decision that enhances the sound quality and atmosphere of your room.

Effective installation techniques play a crucial role in maximizing the soundproofing impact of noise insulation foam. Firstly, it is essential to ensure that the surfaces are clean and dry before applying the foam. Any dust or moisture can interfere with the adhesion process, reducing the foam’s effectiveness. When installing, use a strong adhesive or double-sided tape specifically designed for acoustic foam to secure the panels firmly to the walls or ceilings. This not only helps in maintaining their position but also prevents sound leaks that can occur if the panels are not tightly fitted.

Additionally, strategic placement of the foam is vital. Identifying the primary sources of noise—such as windows, doors, or walls shared with noisy neighbors—should guide your installation. By applying foam in these critical areas, you can significantly reduce sound transfer. Utilizing a combination of different foam shapes, like wedges and pyramids, can further enhance the acoustic treatment by disrupting sound waves. Lastly, considering the room’s overall dimensions will help in determining how much foam is needed and where it is most effective, ensuring that the installation contributes optimally to soundproofing your space.

Noise insulation foam is a game changer for anyone looking to enhance their sound environment. In real-life applications, homes, studios, and offices have experienced remarkable transformations after implementing foam solutions. For instance, a music production studio that once struggled with echo and outside noise pollution saw a significant improvement in its sound quality after installing acoustic foam panels. The clarity of recordings increased dramatically, allowing musicians to produce cleaner tracks without the interference of unwanted sounds.

Similarly, in open office spaces, the addition of sound insulation foam has led to a noticeable decrease in distractions. Employees reported improved concentration levels and overall job satisfaction as background chatter and noise from phones and printers were effectively dampened. This not only fostered a more productive atmosphere but also created a more comfortable working environment, showcasing how essential foam solutions can be in managing sound quality in various settings.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.