When embarking on a home insulation project, understanding the "spray foam insulation cost" is crucial for effective budgeting and planning. According to the North American Insulation Manufacturers Association (NAIMA), spray foam insulation is gaining popularity due to its exceptional thermal performance and energy efficiency. Recent industry reports indicate that homeowners can save up to 20% on energy costs by choosing spray foam over traditional insulation methods, making it a compelling option despite its initial investment.

The cost of spray foam insulation can vary significantly based on several factors, including the size of the area to be insulated, the type of spray foam used (open-cell or closed-cell), and regional pricing differences. The Home Performance Coalition reports that, on average, homeowners can expect to pay between $0.50 to $3.00 per board foot for spray foam insulation. Understanding these variables is essential for homeowners to accurately assess their project's financial viability and long-term benefits. In conclusion, a thorough analysis of spray foam insulation cost not only aids in effective budgeting but also highlights its potential return on investment through energy savings and increased property value.

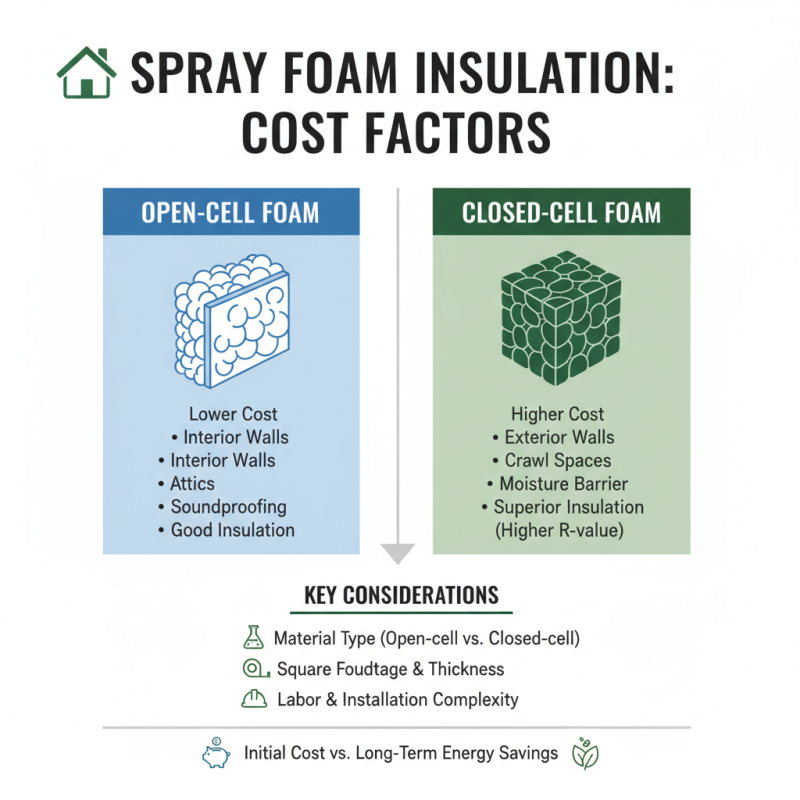

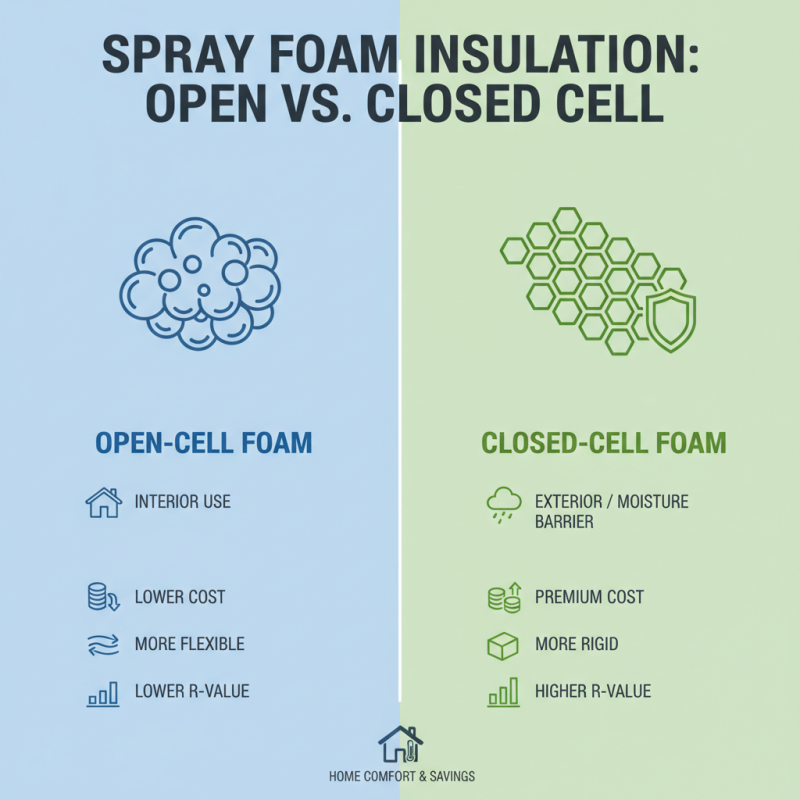

When considering spray foam insulation for your home, several factors will significantly influence the overall cost. The type of spray foam insulation you choose—open-cell or closed-cell—can greatly affect pricing. Open-cell foam is generally less expensive and provides good insulation for interior spaces, while closed-cell foam offers higher R-values and moisture resistance, making it suitable for exterior applications. The decision between these options can impact both initial costs and long-term energy savings.

Another crucial factor is the size and complexity of the area to be insulated. Larger spaces may present more logistical challenges, such as accessibility and the amount of material needed, which can drive up costs. Additionally, the condition of the existing structure plays a role; repairs or modifications may be necessary before applying insulation, adding to your project's expenses.

**Tips:** Before committing to a spray foam insulation project, it's wise to get multiple quotes from contractors to ensure you're receiving a fair price. Additionally, consider scheduling the insulation work during off-peak seasons when contractors may offer better rates. Always verify the contractor's experience and ask for references to ensure quality workmanship, as this can avoid costly issues later.

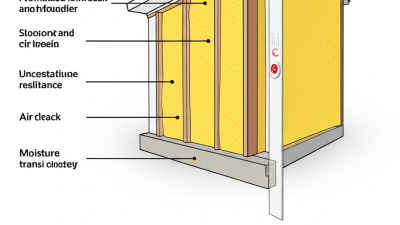

When calculating the amount of spray foam insulation needed for your home project, several factors must be considered to ensure an accurate estimate. First, assess the total square footage of the areas to be insulated. According to the U.S. Department of Energy, spray foam can provide an air-tight seal and insulation values ranging from R-5.2 to R-6.3 per inch, depending on the type used. Therefore, knowing the thickness you plan to use in conjunction with the square footage will help determine the volume of spray foam needed.

Next, it's crucial to factor in the type of application—open-cell or closed-cell foam—for specific performance characteristics. Closed-cell foam generally offers higher insulation values and serves as a moisture barrier, making it suitable for areas prone to humidity. Industry reports indicate that an average home typically requires about 800-2,000 board feet of spray foam, depending on insulation goals and climate conditions.

As standard coverage rates can vary, it's recommended to consult a local contractor or insulation professional, who can provide tailored advice based on your specific project requirements.

When considering spray foam insulation for your home, it's essential to understand the different types available and how they impact overall project costs. There are primarily two types of spray foam insulation: open-cell and closed-cell. Open-cell foam is lighter and less dense, making it more affordable and ideal for interior applications where flexibility is needed. Closed-cell foam, on the other hand, provides a higher R-value and serves as a moisture barrier, making it suitable for exterior use and areas prone to humidity, though at a premium price.

The price of spray foam insulation varies significantly based on the type selected, the size of the area being insulated, and local labor costs. On average, open-cell spray foam can range from $0.50 to $1.00 per board foot, while closed-cell foam can cost between $1.00 to $2.00 per board foot. Additionally, the complexity of the project can influence installation costs, as areas requiring specialized application techniques or additional preparations may incur higher fees. By evaluating the differences in spray foam types along with their respective costs, homeowners can make more informed decisions that align with their insulation needs and budget constraints.

When assessing the installation costs of spray foam insulation, several factors come into play, including material costs, labor rates, and the complexity of the project. According to the Spray Polyurethane Foam Alliance (SPFA), the average cost of spray foam insulation ranges from $0.50 to $3.00 per board foot, depending on the type and thickness of foam used. Additionally, labor costs can vary significantly based on geographic location and the expertise of the contractors involved, averaging between $1.00 to $2.00 per square foot for installation.

Tips: To ensure you're getting a fair estimate, it's advisable to obtain quotes from multiple contractors. This allows for a comparison of not only pricing but also the scope of services offered. Keep in mind that while a lower price may be attractive, quality and experience should be prioritized to avoid potential issues down the line.

Furthermore, project complexity can increase labor costs. Homes with irregular shapes, high ceilings, or challenging access points often require more time and specialized techniques, contributing to a higher overall cost. The SPFA reports that labor can account for approximately 30% to 50% of the total installation cost. Homeowners should consider these aspects while budgeting for spray foam insulation, as understanding these nuances can lead to more informed decisions and successful home improvement projects.

| Area of Home | Square Footage | Material Cost ($/sq ft) | Labor Cost ($/sq ft) | Total Cost ($) |

|---|---|---|---|---|

| Attic | 1,000 | 1.50 | 1.00 | $2,500 |

| Walls | 2,500 | 1.20 | 0.80 | $5,000 |

| Basement | 800 | 1.80 | 1.50 | $2,640 |

| Crawl Space | 600 | 2.00 | 1.20 | $1,320 |

| Garage | 400 | 1.50 | 1.00 | $600 |

Investing in spray foam insulation can yield significant long-term savings for homeowners, particularly when considering energy efficiency. Spray foam serves as an effective barrier against air leaks, which helps maintain a consistent indoor temperature. This layer of insulation reduces the workload on heating and cooling systems, leading to lower energy bills over time. Homeowners can expect to see a return on their investment through decreased energy costs, often yielding savings that offset the initial installation expense.

Moreover, spray foam insulation contributes to enhancing the overall comfort and value of a home. By eliminating drafts and cold spots, it creates a more pleasant living environment. Additionally, with its durability and resistance to moisture, spray foam can prevent issues such as mold and mildew, which can lead to costly repairs down the line. As such, the upfront cost of spray foam can be outweighed by the savings from reduced utility expenses and maintenance, making it an economically sound choice for long-term home improvement.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.