When embarking on a project that involves insulation for ductwork, selecting the right materials is paramount to achieving energy efficiency and cost-effectiveness. Polyolefin duct insulation stands out as an ideal choice due to its unique properties and versatility. This type of insulation not only provides thermal resistance but also contributes to minimizing condensation and sound transmission, making it suitable for various applications in both residential and commercial environments.

Understanding the specific needs of your project is crucial when choosing polyolefin duct insulation. Factors such as temperature ranges, humidity levels, and the overall environment should be taken into account to ensure optimal performance. Additionally, it is essential to grasp the different types and thicknesses available, as these can significantly impact the effectiveness of the insulation. This article aims to guide you through the critical considerations when selecting polyolefin duct insulation, helping you make an informed decision that enhances your project's efficiency and sustainability.

Polyolefin duct insulation is a versatile and effective solution for maintaining optimal temperature control in HVAC systems. Known for its lightweight and durable properties, polyolefin insulation provides excellent thermal efficiency, reducing energy costs while ensuring consistent temperature regulation. This type of insulation resists moisture and is less likely to harbor mold or mildew, making it suitable for a variety of environments, from residential to commercial spaces. The benefits of polyolefin duct insulation extend beyond energy savings; its fire-resistant qualities add an extra layer of safety, making it a reliable choice for many projects.

When selecting polyolefin insulation for your ductwork, consider the thickness and R-value, which measure thermal resistance. Thicker insulation typically offers better performance but may require more space. Additionally, ensure that the insulation you choose is compatible with your duct material. A good practice is to evaluate the specific needs of your project based on climate, energy efficiency goals, and building codes.

Tips: Always check for environmental impact ratings of the insulation materials you consider. Look for products with certifications that denote sustainability and low emissions. Moreover, consult with professionals or conduct a proper assessment of your HVAC needs before making a decision to ensure the best fit for your project.

| Property | Description | Benefit |

|---|---|---|

| Thermal Resistance | Ability to resist heat flow, typically measured in R-value | Improves energy efficiency, reducing heating and cooling costs |

| Moisture Resistance | Resists water vapor penetration | Prevents mold growth and enhances indoor air quality |

| Fire Retardancy | Resistance to ignition and flame spread | Increases safety in building environments |

| Flexibility | Ability to bend and conform to various shapes | Easier installation in tight spaces and around corners |

| Durability | Resistance to wear and tear over time | Longer lifespan and lower replacement costs |

| Weight | Lightweight material for easy handling | Reduces structural load and installation effort |

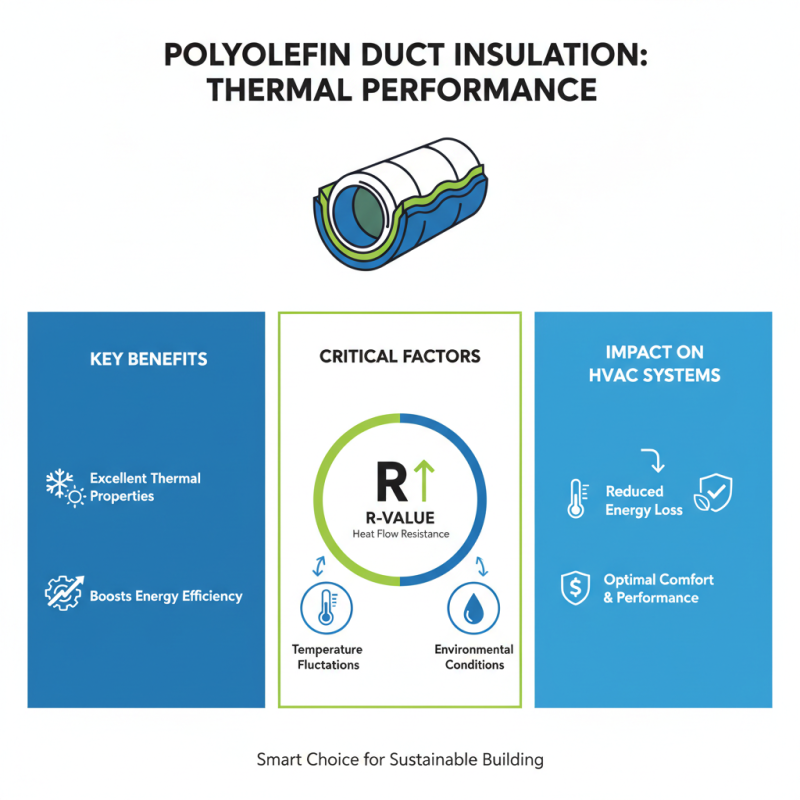

When selecting the right polyolefin duct insulation for your project, several key factors must be taken into account to ensure optimal performance and efficiency. First and foremost, consider the thermal conductivity of the insulation material. According to the North American Insulation Manufacturers Association (NAIMA), polyolefin insulation typically boasts a thermal resistance (R-value) of around R-4 to R-6 per inch, making it a competitive option compared to other insulative materials. This effective thermal performance can significantly reduce energy consumption in HVAC systems, leading to long-term cost savings and enhanced indoor comfort.

Another vital factor to evaluate is the moisture resistance of the insulation. Polyolefin materials are inherently hydrophobic, which means they repel water and resist mold growth, a crucial attribute in maintaining indoor air quality. As highlighted in the 2022 Building Performance Institute Report, inadequate moisture control in insulation can lead to increased energy loss and potential health risks due to mold proliferation. Therefore, selecting a moisture-resistant polyolefin duct insulation not only boosts energy efficiency but also protects the overall health of building occupants.

Lastly, assess the ease of installation and compatibility with existing systems. A study by the U.S. Department of Energy indicates that improper installation can lead to a 20% reduction in a system's efficiency, underscoring the importance of selecting insulation that is easy to handle and install. Polyolefin products typically offer flexibility and adaptability, making them well-suited for various duct shapes and sizes. By considering these factors—thermal performance, moisture resistance, and installation ease—you can make a well-informed choice that aligns with your project’s goals and requirements.

When selecting the right polyolefin duct insulation for your project, it’s essential to understand the different types of materials available. Polyolefin insulations, primarily made from polyethylene or polypropylene, offer excellent thermal properties and resistance to moisture. The two primary types include flexible and rigid insulation.

Flexible polyolefin insulation is ideal for curved ducts and tight spaces, allowing for ease of installation and efficiency in thermal performance. On the other hand, rigid polyolefin boards provide superior structural integrity, making them suitable for larger ducts and areas where durability is a concern.

When comparing these materials, consider their thermal conductivity values, resistance to fire, and overall composition. Flexible insulation generally provides lightweight and easier handling, while rigid insulation offers more thermal protection and can withstand more pressure and impact. Both types are effective in minimizing energy loss, but your choice will depend on your specific application and installation conditions.

Tips: Always check for compliance with local building codes and insulation standards. Additionally, consider the environmental impact of the insulation material you choose, such as its recyclability and any certifications it may have. Finally, think about the ease of installation, especially if you are working in challenging spaces, as this can significantly affect labor costs and project timelines.

When selecting the right polyolefin duct insulation for a project, evaluating thermal performance and energy efficiency standards is critical. Polyolefin insulation is known for its excellent thermal properties, which can significantly impact the overall energy efficiency of heating and cooling systems. Understanding how the insulation behaves under different temperatures and conditions is essential for ensuring optimal performance. For instance, consider the insulation material's R-value, which measures its resistance to heat flow. The higher the R-value, the better the insulation will perform in reducing energy loss.

**Tips:** Look for insulation products that meet or exceed the latest energy efficiency standards. This not only helps in achieving regulatory compliance but also ensures you are investing in a solution that minimizes energy consumption and reduces operational costs over time.

Furthermore, it's important to consider factors such as moisture resistance and ease of installation. These attributes can affect the longevity of the insulation and its effectiveness in maintaining thermal performance. By thoroughly assessing these specifications, project managers can select polyolefin duct insulation that meets both performance requirements and energy efficiency goals effectively.

**Tips:** Always consult with manufacturers or industry experts to ensure that your chosen insulation meets specific project needs and local energy codes, as this can lead to significant savings and enhanced building performance.

When installing polyolefin duct insulation, achieving optimal performance hinges on understanding both material properties and installation techniques. Polyolefin insulation boasts a high R-value, averaging around R-4.2 per inch, according to the Department of Energy reports, making it an excellent choice for minimizing thermal bridging and reducing energy loss in HVAC systems. Proper installation is crucial to harness these benefits fully. It is recommended to ensure that insulation is tightly fitted around ductwork to avoid air leaks, which can significantly undermine the energy efficiency of a system.

Another key aspect to consider is the environment where the insulation will be installed. Humidity and temperature variations can affect insulation performance. A study by the North American Insulation Manufacturers Association indicates that maintaining a consistent temperature and low humidity level during installation can enhance the longevity and effectiveness of polyolefin insulation. It is advised to install insulation in well-ventilated areas to prevent moisture buildup, which could lead to mold growth and compromise the insulation’s integrity. Additionally, utilizing appropriate sealing methods at joints and seams will further enhance performance by reducing thermal conductivity and ensuring the insulation holds its shape and efficiency over time.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.