Expanded Polyolefin Foam (EPOF) has emerged as a versatile material in various industries, thanks to its exceptional properties and adaptability. According to Dr. Sarah Thompson, a leading expert in polymer materials and a consultant in the foam industry, "The unique cellular structure of expanded polyolefin foam not only contributes to its lightweight nature but also enhances its insulating and cushioning capabilities." This transformative material is increasingly being recognized for its applications across sectors such as packaging, automotive, aerospace, and construction.

The benefits of expanded polyolefin foam are manifold. These include excellent thermal insulation, moisture resistance, and shock absorption, making it an indispensable choice for manufacturers looking to optimize performance while reducing weight. Moreover, its sustainability profile is noteworthy, as it can be recycled and contributes to the reduction of material waste. As industries continue to evolve, the demand for innovative materials that offer both efficiency and environmental responsibility will only grow, positioning expanded polyolefin foam as a key player in the future of material science.

Expanded Polyolefin (EPO) foam is distinguished by its unique combination of lightweight, durability, and versatility, making it a preferred choice across various industries. Characterized by low density and closed-cell structure, EPO foam boasts excellent thermal insulation properties, with studies indicating a thermal conductivity as low as 0.035 W/mK, making it effective for energy-saving applications. Furthermore, its resistance to moisture absorption—often less than 1%—enhances the material’s durability and longevity, particularly in outdoor environments where exposure to moisture and temperature fluctuations is a concern.

In addition to its thermal performance, EPO foam exhibits outstanding impact resistance and cushioning capabilities. According to industry reports, the compressive strength of EPO foam can reach up to 300 kPa, meaning it can effectively absorb and dissipate energy upon impact, providing protection for sensitive equipment in packaging and transportation. This characteristic is particularly valuable in sectors such as automotive and electronics, where product integrity during transit is paramount. Enhanced fire-retardant properties can also be integrated into EPO foam formulations, making it suitable for applications in \ construction and public transport, where safety regulations demand higher standards of flame resistance.

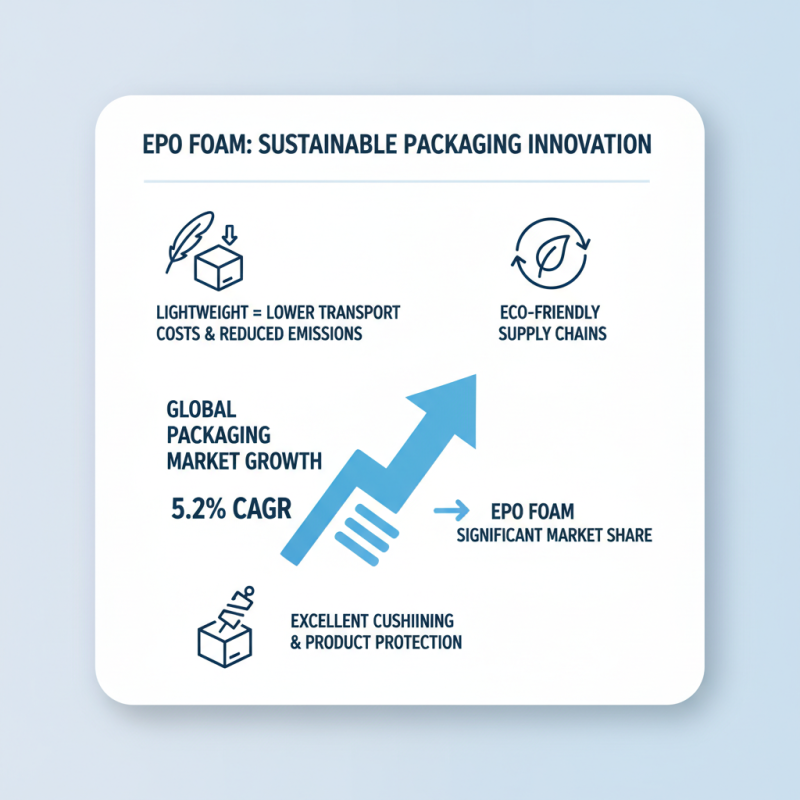

Expanded Polyolefin Foam (EPO) has emerged as a leading material in the packaging industry due to its unique combination of lightweight properties and excellent cushioning capabilities. According to the "Global Packaging Material Market Report 2022," EPO foam's lightweight nature contributes to lower transportation costs, as overall shipping weights are reduced, thereby cutting fuel consumption and carbon emissions. This is increasingly important as businesses strive for sustainability in their supply chains. The report indicates an expected compound annual growth rate (CAGR) of 5.2% in the packaging material market, with EPO foam expected to capture a significant share due to its benefits.

Additionally, EPO foam demonstrates exceptional shock absorption properties, making it an ideal choice for protecting delicate items during transit. Recent studies highlight that EPO foam can absorb up to 85% of impact energy, which minimizes damage to packaged goods, thus enhancing consumer satisfaction and reducing return rates. The versatility of EPO foam allows it to be tailored for various packaging applications, from food packaging to electronics, solidifying its place in a wide range of industries. As companies continue to prioritize product safety and sustainability, the adoption of Expanded Polyolefin Foam in packaging will likely continue to grow, offering a reliable solution for modern packaging challenges.

Expanded Polyolefin (EPO) foam is increasingly recognized for its superior thermal insulation properties, making it an ideal choice across a variety of applications. The closed-cell structure of EPO foam traps air within its cells, providing an effective barrier against heat transfer. This characteristic is essential in sectors such as construction and automotive manufacturing, where maintaining temperature is critical for energy efficiency and comfort.

The lightweight nature of EPO foam further enhances its usability, allowing for easier transportation and installation without compromising on performance.

In addition to its insulation capabilities, EPO foam also contributes to increased energy savings, reducing the need for excessive heating or cooling systems. This not only lowers operational costs but also supports sustainability efforts by minimizing energy consumption.

The foam’s resistance to moisture and chemicals further extends its lifecycle and effectiveness, ensuring that thermal insulation remains intact in various environments. Overall, the impact of EPO foam on thermal insulation is profound, providing a reliable solution that meets the demands of modern applications while promoting eco-friendly practices.

Expanded Polyolefin (EPO) foam has emerged as a vital material in the automotive industry, thanks to its unique combination of lightweight, durability, and energy absorption properties. One of the main advantages of EPO foam is its ability to enhance vehicle safety. In crash simulations, EPO foam effectively absorbs impact energy, thereby reducing the force transmitted to occupants. Additionally, its lightweight nature contributes to improved fuel efficiency and reduced emissions, making it an environmentally friendly choice for manufacturers aiming to meet stringent regulations.

Another significant benefit of using EPO foam in automotive applications is its versatility. It can be molded into various shapes and sizes to suit different components, from interior panels to insulation materials. EPO foam also exhibits excellent thermal and acoustic insulation properties, leading to enhanced passenger comfort. Furthermore, its resistance to moisture and chemicals ensures longevity, making it a cost-effective solution for automotive manufacturers.

Tips for automotive designers: When integrating EPO foam into your projects, consider the specific performance requirements of each component. For high-impact areas, use a thicker foam to maximize energy absorption. Additionally, ensure proper bonding techniques are employed to achieve optimal durability and performance. By leveraging the advantages of EPO foam, you can create safer, more efficient, and comfortable vehicles for consumers.

Expanded Polyolefin Foam (EPP) is increasingly recognized for its sustainability and environmental benefits, making it an excellent choice for various applications. One of the key advantages of EPP is its lightweight nature, which contributes to energy efficiency in transportation and packaging. The reduced weight leads to lower carbon emissions during shipping, aligning with global efforts to mitigate climate change. Furthermore, EPP is 100% recyclable, meaning it can be repurposed into new products rather than ending up in landfills, thus minimizing waste and promoting a circular economy.

In addition to its recyclability, EPP is produced from non-toxic materials that are safe for both human health and the environment. The manufacturing process generates lower emissions compared to many traditional foam materials, making it a more eco-friendly option. Furthermore, EPP's durability extends its lifecycle, which decreases the need for replacements and reduces resource consumption over time. As more industries seek sustainable materials, the adoption of EPP can lead to significant improvements in both product performance and environmental impact. This dual focus on functionality and sustainability positions EPP as a valuable material in the quest for greener alternatives in manufacturing and product development.

This bar chart illustrates the top 10 benefits of Expanded Polyolefin Foam (EPO) used across various applications, highlighting its sustainability and environmental advantages.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.