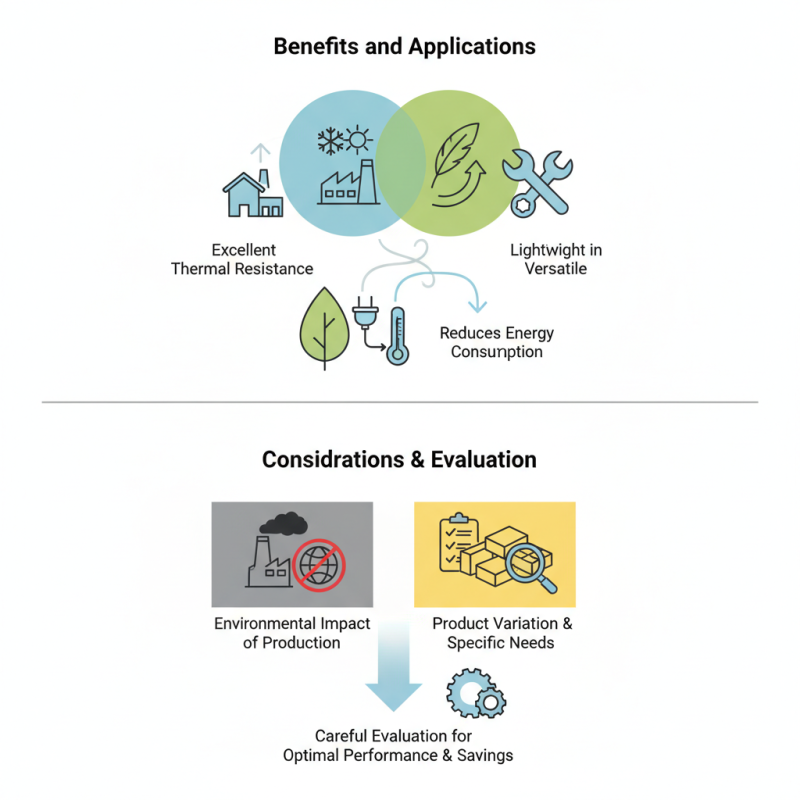

Polyolefin foam insulation has emerged as a popular choice in various industries. This material offers numerous benefits, including excellent thermal resistance and lightweight properties. Many builders appreciate its versatility and efficiency.

The strength of polyolefin foam insulation lies in its ability to reduce energy consumption. It performs well in both commercial and residential applications. However, the environmental impact of production is a concern that requires attention.

While polyolefin foam insulation provides significant advantages, not all products are created equal. Some foams may not meet the specific needs of a project. It is crucial to evaluate different options carefully. Ensuring the right choice can lead to better energy savings and enhance overall performance.

Polyolefin foam insulation materials are versatile and widely used in various applications. These materials are lightweight, which makes installation easier. They consist primarily of polyethylene or polypropylene, both of which are known for their durability. Many industries, including construction and automotive, have integrated these insulation solutions due to their efficiency.

In construction, polyolefin foam offers excellent thermal resistance. This property helps maintain temperature control in buildings. However, the moisture resistance varies, and it is essential to assess this before application. A common concern is that not all polyolefin foam products are recycled effectively, leading to environmental challenges. Awareness of material sourcing can help mitigate some issues.

Additionally, these insulation materials are often used in packaging to protect sensitive items. The cushioning effect can be beneficial during shipping. Yet, some users might find the cost higher than traditional options. Understanding these materials' pros and cons can lead to more informed choices. Observing real-world applications can highlight areas for improvement and innovation.

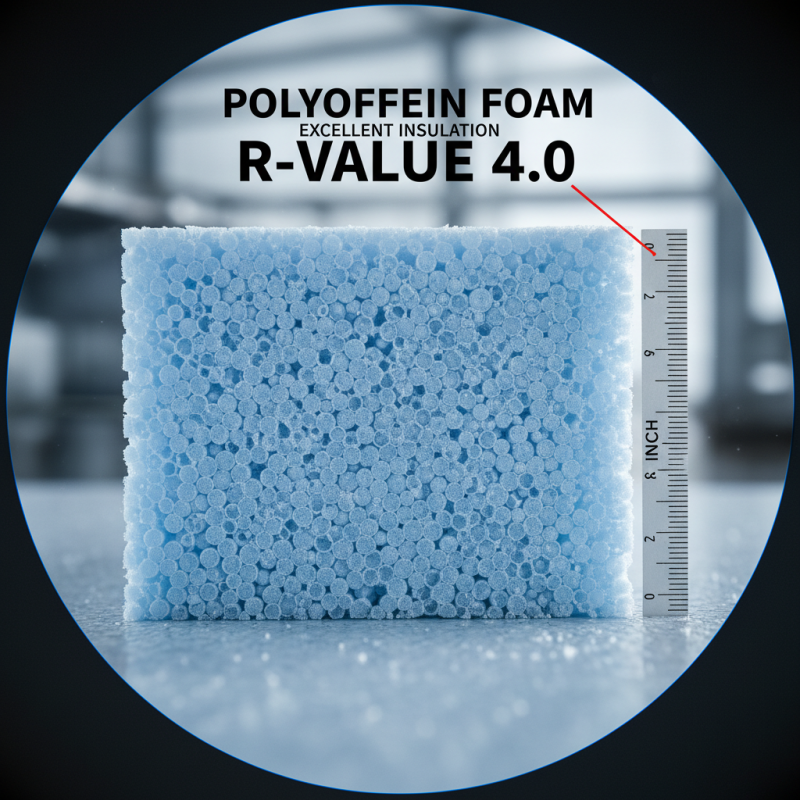

Polyolefin foam is a lightweight material, renowned for its excellent insulation properties. It's often used in construction and automotive applications. The material possesses a closed-cell structure, which prevents moisture absorption. This characteristic makes it highly effective in reducing heat transfer. According to a recent industry report, polyolefin foam insulation can achieve an R-value of up to 4.0 per inch. This is quite beneficial for energy efficiency.

The physical properties of polyolefin foam are impressive. The material is durable and resistant to chemicals, making it ideal for harsh environments. It also boasts flexibility, allowing easy manipulation during installation. However, some experts argue that the foam's long-term performance in extreme temperatures is still under investigation. This raises questions about its lifecycle and environmental impact.

Moreover, polyolefin foam is recyclable, which is a significant advantage. Yet, recycling processes are often not straightforward, and availability varies by region. Companies may focus on production without addressing these recycling challenges. Maintaining a balance between performance and sustainability is crucial for long-term industry success.

Polyolefin foam insulation stands out in the construction industry for several reasons. First, it offers exceptional thermal resistance. Reports show that it can reduce energy costs by as much as 25%. This efficiency is crucial for both new constructions and retrofitting projects. Builders appreciate the lightweight nature of polyolefin foam, allowing for easier handling and installation.

Another significant advantage is its moisture resistance. Polyolefin foam does not absorb water, reducing the risk of mold growth. This feature helps maintain indoor air quality, an essential aspect of modern construction. However, attention must be paid to proper installation techniques to maximize these benefits. Gaps or misalignments can diminish insulation performance.

Tips: Always check local building codes for insulation specifications. Consider a professional installation to ensure effectiveness. Remember, not all applications may require this insulation type, and consulting a service may provide better clarity on your specific needs. Balancing cost and performance is key. Each project may present unique challenges that require tailored solutions.

Polyolefin foam insulation has gained traction across various industries due to its unique properties. This lightweight material offers excellent thermal resistance and moisture control. In the automotive sector, polyolefin foam is used for sound insulation and thermal management. Reports indicate that the automotive foam market is projected to reach $20 billion by 2026. Such growth reflects the increasing demand for energy-efficient vehicles and superior comfort.

In the building and construction industry, polyolefin foam serves as an effective insulation solution. It contributes to better energy efficiency in residential and commercial spaces. According to a recent study, buildings utilizing foam insulation can reduce heating and cooling costs by up to 30%. This statistic highlights the potential of foam insulation, but it also raises questions about the long-term sustainability of materials and their environmental impact.

Packaging is another significant application for polyolefin foam. It provides protection for fragile items during shipping. The global packaging foam market is expected to grow, but the durability and recyclability of these materials need continued exploration. There might be a disconnect between demand and sustainability practices. As industries seek to innovate, they must consider the lifecycle of these insulation materials.

Polyolefin foam insulation is becoming increasingly popular among builders and homeowners. It offers lightweight properties, excellent thermal resistance, and moisture resistance. Comparing it with traditional materials like fiberglass or polystyrene reveals significant advantages in efficiency and installation. Polyolefin foam is more flexible, making it easier to fit into tight spaces and irregular shapes.

However, one should consider potential downsides. Polyolefin foam might not have the same fire resistance as other materials. It's also important to think about cost versus value. Sometimes, cheaper options can lead to higher long-term energy bills.

*Tip:* When choosing insulation, assess your specific needs. Consider factors like climate, building structure, and budget.

Beyond polyolefin, materials like spray foam can provide a complete seal. But installation can be complicated and messy. Check the expertise of the contractor before proceeding.

*Tip:* Always ask for samples. Touch and feel the materials before making a decision. It helps to visualize the final outcome.

| Insulation Material | R-Value | Thickness (inches) | Moisture Resistance | Application Areas | Cost ($/sq ft) |

|---|---|---|---|---|---|

| Polyolefin Foam | 3.0 - 4.0 | 1 - 2 | Excellent | HVAC, Plumbing, Wall Insulation | 0.50 - 1.00 |

| Fiberglass | 2.9 - 4.3 | 3 - 6 | Moderate | Attics, Walls, Roofs | 0.30 - 0.60 |

| Spray Foam | 6.0 - 7.0 | 1 - 2 | Excellent | Basements, Crawlspaces, Walls | 1.00 - 1.50 |

| Mineral Wool | 3.0 - 3.3 | 3 - 6 | Good | Fire Resistance, Soundproofing | 0.50 - 0.90 |

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.